|

Actuation Test

Equipment Co. |

A brief history of the Index Test Box

project

|

1975 - Woodward Governor Company introduced a new digital electronic 3-D cam for Kaplan turbine runner blades, replacing the hydromechanical 2-D Cams deployed at that time. USACE supplanted them with their own 3-D Cam controller because Woodward 3-D Cam had a potentiometer feedback on the blade-angle cam. USACE had a policy of never using potentiometers as feedback elements for critical control inputs. Woodward scoffed at this and didn't offer the logical solution of switching to a non-contacting resolver, RVDT or Rotary Optical Encoder with a significant upcharge. Instead, Woodward's position was, "We're the experts so do it our way. " USACE embarked on a DIY project that has arguably led to the Fish Mortality problem, Lawsuit and ongoing spill of ~$350M annualy. |

|

|

1985-To increase sales of 3-D Cams,

integral index-testing was offered to tune-up the unit by optimizing

its 3-D Cam profile. The first Index Test Box (ITB) Prototype was

initially field tested at Clarence Cannon dam on Mark Twain Lake in Missouri,

USA. This test validated the ITB and the Constant Power Method of

testing by a direct comparison of test results from the new Index Test

Box and the industry standard classical method of index testing.

According to a DOE Hydropower Engineer the Results were

positive, leading to productionization of the ITB and an offering for

public sale. |

|

|

|

The Constant

Power method was used for this test. This test is run "on the

governor," with the unit operating normally - as far as the dispatcher

and control room can tell. The ITB sends a blade-offset value to

the 3-D cam, which pushes the blade above or below the on-cam position while

allowing the governor to hold power constant using the gates.

This sweeps the gates and blades together along the parabolic-shaped

"Constant Power" curves shown at left. Corresponding efficiency

curves on a second page locate the peak efficiency blade to gate point. |

|

The prototype ITB Field

test at Clarence Cannon Dam was scheduled to run concurrently with the USACE

acceptance tests on the two turbines in this newly comissioned Dam and

powerplant. Based on the closeness of the ITB and conventional test results,

BPA purchased an ITB 6-months later. |

|

|

1986 Bonneville

Power Administration (BPA) in Portland Oregon purchased the first production

ITB in 1987 for a "proof of concept" test for potential

use in the Federal Columbia River Power System (FCRPS) power plant. This test

was conducted by DoE at Portland General Electric Bull Run Power House

#2 (PGE-PHP-2). Successful test results were reported by engineers from PGE,

DoE and

Woodward. |

|

|

|

The Constant

Power method was used for this second field test in a DoE "Proof of

Concept" test at Bull Run. Success was such that DoE offered to purchase

113 ITBs from Woodward Governor, which would have included new governors and

3-D cams. Total cost of complete FCRPS turbine control system upgrades and

ITB installations was estimated >$25-million. USACE HDC declined

this offer, preferring to design and build their own automated index

testing device. |

|

1987-Woodward's

Index Test Box was introduced in Hydro Review

magazine concurrent with the PGE-PHP-2 test.

This article reports on the 1985 prototype field-test at

Clarence Cannon Dam, describes index testing conventional methods and the new

Constant Power method, and explains the new Index Test Box methods and

techniques. |

|

|

Woodward's hydro

division was moved to new facilities in Stevens Point Wisconsin, USA and the

ITB project was transferred to other Woodward personnel. The next field-test

was unsuccessful and the hydro division faltered, failed and was sold to

General Electric. The ITB patent went along with this sale, but the

technology it protected was never utilized. The patent expired in 2003

and the ITB technology came into the public sector. Actuation Test Equipment

Company was established to develop and market this new technology in

1993, but before any offerings were made, USACE Hydro Design Center (HDC)

contacted ATECo to inquire if an updated ITB could be purchased from the

inventor(s) listed on the ITB patent. |

|

|

2005 -The

original Index Test Box design was updated to ITBRev-1. Two

sole-source solicitations led to USACE

purchasing one ITB on a sole-sourced contract for a second

"proof of concept" test at McNary Dam on the Columbia River in

Umatilla, Oregon. Testing at McNary in December 2005 was ultimately

successful, as described in ATECo's test report, HDC's Memorandum

for the Record and HDC's reports to DOE BPA Hydro

Optimization Team (HOT) meetings. All of the Government documents were

acquired via FOIA requests. |

|

|

The Constant

Power method was used for this USACE "Proof of Concept"

Test at McNary. Test was mostly successful, but low flows were

unmeasurable due to extremely noisy Winter-Kennedy signal. A

rolling-average filtering algorithm was designed for the ITB signal

conditioner that allowed robust signal response while blocking high-frequency

noise. |

|

|

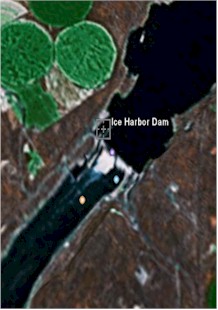

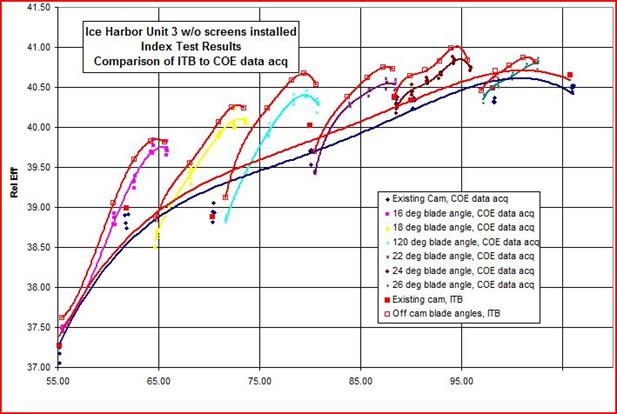

2006-A second field test at Ice Harbor

Dam was conducted to verify the fixes and that USACE personnel could operate

the ITB unassisted. The test was a parallel data collection

where USACE's normal data acquisition system was used for the

index-test while the Index Test Box was connected in parallel to

continuously record SCADA system data streams. The ITB data was downloaded and

sent to ATECo for analysis. The test results were sent to USACE HDC for

comparison with the official COE data reduction. The comparison and all COE

results were withheld from ATECo with no comment as to why. |

|

|

|

The comparison

was obtained years later via FOIA. It shows good correlation between the

reltaive test results from both the ITB and the COE instrumentation.

Subsequent FOIA documents from BPA HOT show duplicity by government personnel

who attempted to commandeer the ITB technology. |

|

The second

field-test was reported with a PowerPoint presentation by USACE

personnel to the HOT on 3 March 2006. This document was acquired from BPA by

FOIA request. The conclusion on the ITB field testing was that ITB test results

were; this test was even more successful. FOIA requests to HDC and

BPA were necessary to learn that HDC had reported to

BPA HOT that the "Results virtually identical to those obtained

using COE data acq system," and that ATECo's ITB was "Ready for

‘unattended, automated’ data collection." |

|

|

2008-A

second magazine article to introduce the new Index Test Box currently

being offered, highlighting the new Constant Power method and

statistical analysis techniques to determine SteadyState conditions. New

features include updated computers & software, relying on "lessons-learned"

from the experience with the Columbia river field

tests as a guide. The instrument configuration is intended for use at index

testing and long-term monitoring of turbine performance. |

|

2008-North

American Hydro engaged with ATECo to initiate a project to optimize the

three Kaplan bulb-units on the St. Mary’s River in Sault Ste Marie,

Ontario Canada. This Google Earth aerial view shows the layout of the

approach and discharge canal of the power plant setting. Flow and wave

dynamics in the approach canal on the left-side present a difficult problem

for controlling these turbines and for capturing SteadyState index-test data

for efficiency performance evaluation of these turbines.

The index-test

procedure is to always approach every test point in the increasing gate

direction, which means the forebay sloshing is always at its perigee when

data points are captured. This error culminates in a 3-D Cam profile

shifted to a lower than documented head that has a detrimental effect on

overall turbine operating efficiency. This problem can

be completely avoided by using the Index Test Box Constant Power Method that

synchronizes the motions of gates and blades to sweep across the “On-Cam”

line to capture the efficiency data points for the existing power level

without affecting flow (or power) appreciably. The ITB testing

method is a continuous process that runs in the background rather than a

scheduled testing event. The SCADA system and powerplant data logger are

programmed and setup to record Forebay, Tailwater, Gate Stroke, Blade Angle,

Relative Flow and Generated Power continuously during normal operation of the

unit. , and data collection

method records data 24/7 collects and analysis the data in hours-long blocks,

gleaning SteadyState data points from Excellent

instrumentation and data logging equipment that were already present in the

power plant facilitated a new index-testing

method. Data collection uses the existing power plant

instrumentation during normal operation. A few modifications to the

instrumentation and turbine control system made index testing during normal

operation easy and economical. |

|

PT Interface

Synchronizer WGC MOD II Retrofit at Mica Design Manual |