FORWARD

The following is a description of the latest version of the Index Test Box

(ITB) and its capability as an instrument to advance the state of the art in

monitoring hydroelectric generating units. It is designed to optimize the

performance of individual generating units powered by either Kaplan or Francis

turbines and to monitor their performance and alert an operator whenever there

is a degradation in performance that indicates a need for maintenance. The

original device was developed to be connected to the governor and in an

unattended manner to collect operational data and sort the data for

analysis. It was field tested several times and compared to manually

conducted index tests and found to work perfectly. In fact, it produced

data with virtually no uncertainty or scatter.

The

instrumentation technician invented the software while working at Woodward

Governor Company. Evaluation of signal composition in the frequency domain led

to the development of a nonlinear digital filter to glean steady-state data

from the noisy continuous data streams emanating from the machine.

Unfortunately, the ITB project did not achieve commercial success for Woodward

Governor Company. Some familiarity at index testing is necessary to fully

appreciate the ITB’s accuracy and laborsaving value. There are scant few

engineers with such expertise, especially in management/procurement positions.

Development

work continued on the device, particularly on the aspect of being able to feed

recorded data from the power station SCADA (Supervisory Control and Data

Acquisition System) directly into the ITB as though it was actual field

data. Playback is sped up to over 100 times normal speed. The sorting

process to decide what to keep and what is too noisy is fully automated. This

remote index testing capability was demonstrated to function perfectly in the

Dorena field-tests for index testing a Kaplan turbine. A long-term condition

monitoring system is available to track operational performance of generating

units over time so that maintenance may be scheduled on an as needed basis.

Lee

Sheldon, P.E.

The Index Test Box

and Hybrid Index Testing Method are Diagnostic Tools for Optimizing and

Condition Monitoring of Hydroelectric Turbines

Abstract

The

Index Test Box (ITB) and Hybrid Index Testing (HIT) method combine to become

HIT/ITB; a Diagnostic Tool for Index Testing and Optimizing Kaplan Turbine 3-D

Cam Surfaces and Condition Monitoring of Hydroelectric Turbines.

The

ITB was developed as an accessory for Woodward’s 505-H Kaplan governor to

collect field data for index testing.

Available

diagnostics are dual purpose and multi-function. The first purpose is to

check-out the governor, 3-D Cam (if the turbine is a Kaplan) and

electro-hydraulic actuators to verify the control system is working properly.

The second is turbine efficiency analysis and index testing to optimize Kaplan

turbine 3-D Cam surfaces and capture overall efficiency profiles for input to

Type-2 optimization systems. The greatest advantages of the ITB and HIT Method

for index testing are cost and time saving and improved data coherence and

elimination of the drudgery of capturing field data by hand.

Scope

This

proposal covers only Kaplan and Francis turbine index testing, optimization and

condition monitoring. It is most likely this methodology will work on a Pelton

type as well, but won’t claim it until it’s been done.

The

foci of this proposal are index testing

to:

·

Tune-up individual Kaplan turbine

head and gate to blade 3-D Cam data surfaces to maximize its individual

operating efficiency all across its operating envelope.

·

Capture an on-cam gate-sweep to

characterize the Overall Efficiency Profile for input to a higher-level

powerplant-wide optimization scheme.

·

Define the baseline benchmark for

comparison during subsequent trending of operating efficiency.

·

Condition monitoring to alarm the

operators if operating efficiency gets out of limits.

The

purpose ofthis is to introduce the HIT method and the

ITB, which is a test instrument especially designed for tuning-up and

monitoring hydroelectric turbines. The ITB is used to evaluate governor and

blade control system operation and aid in setup, calibration, maintenance and

monitoring of these machines. The ITB is an instrument created at Woodward

Governor Company in 1984 to facilitate installation, commissioning and

diagnosis of hydroelectric turbine control systems by providing a means of

getting better field data back to the engineers at Woodward when problems

arise. Although the ITB was always found to be a useful tool for collecting

field data for optimizing Kaplan turbines it was not a commercial success for

Woodward.

Although

it was originally designed for Kaplan turbines the ITB can be used on any type

of hydroelectric generator. the original work assignment for the ITB project

was when Woodward’s hydro engineering manager, George Mittendorf* handing me a

copy of Lee

Sheldon’s 1982 tutorial on Kaplan index testing and optimization with the

directive, “Make us something that does this.” George said to do the Kaplan

turbine first, the rest of them will be easy after the ITB can do a Kaplan.

*(Woodward Hydro Engineering Manager in

1984 is credited twice in the current

2011 ASME PTC-18 Standards and PTC-18 Committees pg. viii)

The

ITB is a labor-saving data collection tool designed as an accessory to

Woodward’s Kaplan governor. The ITB has been validated by parallel

field-testing with conventional index tests on 5-separate occasions. Each field

test validation consists of:

1.

using the ITB to index test a Kaplan

turbine at a single head to derive the overall efficiency curve and optimize,

or tune-up the 3-D Can head and gate to blade surface,

2.

repeat the index test and

optimization using the traditional testing methods and then

3.

the results were compared and

evaluated by government hydropower experts.

Each

and every time the ITB results were deemed to be in full agreement with the

traditional method.

ITB

Features and Functions

·

Stripchart recorder

·

X-Y Plotter

·

SteadyState filter

·

Remote Viewing of data

·

All standard PC-type utilities are

still available

Introduction

The

most recent developments to the ITB are a 5th successful field-test

to validate both the ITB and the new HIT method for index testing a Kaplan

turbine. In this new era of Social Distancing, crowd avoidance and other

biological exposure concerns, a way to remotely index test and diagnose

hydroelectric turbine control systems (i.e. without going to the dam) would be

a welcome addition to a control-engineer’s tool kit. This is precisely what the

Index Test Box (ITB) and Hybrid Index Testing (HIT) method are for... The

Canada/US Border is expected to be closed for months to come. This remote

testing capability will become handy to have at some point when it is needed

most. The ITB was originally designed as a maintenance tool to be used by

Woodward’s hydro engineering department to get diagnostic field-data instantly

viewable back in the shop during troublesome startups. In today’s contagion

conscious climate, it would be helpful to be able to index test and diagnose

control system problems across-borders without the hassles of crossing borders.

With the ITB and Internet communications this capability exists now and can

reach out to anywhere in the world.

How

HIT Works

Figure 1 Click Image to see a short video about the ITB at a

3-unit plant in Canada.

The

HIT method permanently reconfigures the powerplant’s existing instrumentation,

SCADA system and datalogger to set up for turbine efficiency measurements. By

maintaining NIST

Traceability*

on all sensors at all times, an index test can be performed at any time and

trended back to the initial benchmark data to evaluate degradation when

considering refurbishment.

Every

scan of data is of excellent quality and suitable for index testing and

optimization.

The

HIT Method breaks-down the setup steps for an index test so it can be

accomplished as a series of routine task-orders carried out by regular

powerplant personnel during the normal daily work schedule. This alleviates the

need for index-testing specialists to go to a dam to setup and execute an index

test and reduces out-of-pocket costs for an index test by approximately 90%.

According

to Lee, the reduced data from the ITB has less scatter than traditionally

collected index test data. A side benefit of the HIT method is that the

powerplant personnel get greater familiarity with the optimization methods and

equipment to perform index testing field work. When the setup is complete,

execution of an index test becomes a simple task for the operators to perform

as a scheduled task somewhere between annually and quinquennially. Routine

maintenance of the instrumentation will maintain NIST Traceability on all

sensors used for the index test measurements so every scan of data is equally

accurate and valid as any other.

The

workload to run an index test

Running

an index test using the HIT method is not difficult or all-engaging. An index

test consists of 25 or more manual setpoints for gates and blades with an

8-minute dwell at each gate-blade position pair. Assume 10 minutes per test

point for these estimates. Total time for task-order – 10 minutes each for 25

test pointes = 250 minutes = 4.1 Hours. While running the test, the operator

does not need to record any data or calculate any answers, just set the gates

and blades and wait 8 minutes while the datalogger records scans to memory. (In

truth, with the HIT method the two most important accessories for running an

index test will become a minute-timer and a book or magazines to read while

waiting for the next data point.)

Exercising

the turbine for an index test would best be accomplished by an automatic

programmed cycle in the turbine control system. (This was how it was planned at

Woodward, but office politics…) It could be A virtual “Drum-Program” created in

software to output setpoints to gates and blades automatically on a time

schedule. The Drum Program code could reside in either the SCADA system or the

governor PLC. This process reduces the cost of a Kaplan turbine index test to

1/10th the cost of a traditional index test.

ITB

Is Now a Service Over the Internet

The

ITB in 2020 has evolved into a service over the Internet. The powerplant

personnel get a checklist of signals to setup and a set of gate-blade pairs to

execute and all the Internet and telephone assistance they need to get the test

up-and-running. No out of pocket expenses are incurred for the setup and

data collection parts of the index test because the powerplant’s own equipment

and personnel are used exclusively throughout. The customer only pays ATECo for

the data reduction and analysis work that ATECo actually does.

The

data files recorded during execution of the gate-blade pairs are uploaded to

ATECo for analysis and reduction to a new optimum 3-D Cam surface that will

achieve the highest possible efficiency from the unit under any conditions of

head and flow. After the new 3-D Cam surface is installed in the machine

another on-cam sweep of the machine is analyzed to verify results. The final

test report will quantify the efficiency improvements from the index testing

and optimization procedures.

Index

testing using the HIT Method is a neat, clean no-travel-required way to

maximize electrical output while minimizing environmental harm and wear and

tear on the turbines.

Remote

Testing Method

Field-testing

experience with the ITB and hydro-electric turbines has revealed a better way

to index test a turbine that does not require that the test engineers go to the

dam to run the test personally, saving both money and time. Today with viral

exposure concerns everywhere the alleviation of any need to go anywhere is a

plus. The Hybrid Index Testing (HIT) method of index testing has evolved as a

natural progression of form follows function. The original reason that remote

index testing was needed was to get one-way data communication from the

powerplant’s SCADA system into the ITB with no possibility of a computer virus

getting fed back into the SCADA system from the ITB. The no-go-to-the-dam

feature is especially desirous in these days of social distancing to avoid

potential exposure to infectious viruses and such. (Who’d a thunk that 14 years

later the anti-computer-virus technique would become useful again, but this

time to protect from biological viruses? The HIT method will work equally

well for this situation.)

A

happy circumstance in this is that by saving many thousands on logistics

(travel, lodging meals etc.) and getting back the travel time normally spent

going to and coming from the dams, many more turbines can be index tested and

optimized within the same Maintenance Budget.

Using

this new Hybrid Index Testing (HIT) method all index testing can be

accomplished from a central location working with either live over the

internet data or canned pre-recorded data.

If

the governors were programmed to execute the set of gate-blade pairs designated

for the index-test, an automatic index test could be accomplished.

Remote

Viewing of Data

·

The technician the field sets up the

instrumentation and data recorder, exercises the machine while collecting the

data. Data is offloaded to a thumbdrive and then is uploaded to the ITB located

back at the shop. The data can be played back in the ITB in the shop and the

engineers there can see the stripchart and X-Y Graph displays with only a few

minutes delay.

·

If the ITB in the field is allowed

to be connected to the Internet while connected to the hydro unit, it’s display

can be ported to the ITB back in the shop and the engineers there can see it

live at the same time.

The

SteadyState detector

What

makes remote index testing possible is the SteadyState algorithm that is the

key-element in the ITB program, a non-linear digital filter designed in the

frequency domain to sift through the dense spectral content in the time domain.

This

non-linear algorithm was written specifically for this purpose utilizing a

2-pass statistical analysis routine comprised of Linear Regression (LR) and

Standard Deviation (SD) calculations to quantify slope (SteadyState-ness)

and SD (Noisiness) values as “figures of merit” for the average value.

Comparison

of the Slope and SD values to preset limits determines if the unit is running,

“steady-state.” Data points captured and deemed to be steady-state are renamed

“SteadyState data points.”

SteadyState

data is collated into a separate data file for subsequent reduction to a new

3-D Cam surface by hand.

The

SteadyState data gleaned by this process is delivered in the same format as the

traditional method data.

SteadyState

Algorithm

utilizing

Linear Regression (Slope) and Standard Deviation (SD) to “SteadyState-ness” of

a data point. A SteadyState data point consists of an average value accompanied

by Slope and SD values as “figures of merit.” The Slope and SD are compared to

operator preset limits to sort the SteadyState data from the noisy continuous

data streams.

The

HIT method index test at Dorena is the example being put forward now to show

how your Kaplans can be optimized.

Why

these tests were run at Dorena

These

tests were wanted by the new owners when this recently commissioned generating

equipment changed hands. In addition to the seller hiring ATECo to index test

the unit 4-times to optimize the 3-D Cam surface profile by mapping the unit’s

entire operating envelope, the buyer hired Hatch Inc., a big-league consulting

outfit to run Load Reject and index tests on the units at 102 ft head which

serves to validate our work.

How

the Maintenance Program Will Work - First, an index test to benchmark unit

performance

The

turbine testing process starts with a thorough checkout of the gate and blade

control systems for dynamic responsiveness and steady state accuracy because

after all – if you can’t put the gates and blades where you want them, there’s

no point in index testing.

A

one-time setup is needed to check out the available input and output signals

and make any necessary additions or adjustments. For example, operators must be

able to manually control gates and blades to exercise the machine to the

prescribed gate and blade positions for index testing. Many turbine governors

do not have manual gate and blade controls. Most do not have an external

readout of blade position. These modifications are best accomplished by the

governor supplier.

The

overall Maintenance Program will utilize the new Hybrid Index Testing (HIT)

method that was demonstrated recently at Dorena Dam. Index test data is used

not only to tune-up Kaplan turbine head and gate to blade 3-D Cam surfaces to

maximize an individual machine’s efficiency performance but also to

characterize its overall efficiency profile for unit Condition Monitoring,

Trending and to prepare source data for plant-wide optimization schemes for

multi-unit powerplants. The objective was to optimize the entire

head-and-gate-to-blade 3-D Cam surface for a Kaplan turbine. To keep costs down

and get greater familiarity with their equipment, the powerplant staff setup

the instrumentation for the index tests.

For

this test at Dorena the governor vendor was brought in to modify the governor

to get manual control of gates and blades for index testing and to setup the

SCADA system for continuous 2-Hz scans with the desired channel listing and

order. (Forebay, tailwater, gate stroke, blade angle, flow in cfs and power in

MW). Whenever it was appropriate a specimen of the stripchart data was uploaded

to ATECo for evaluation and critique.

This

is where the thorough control system checkout comes in

Turbine

control systems have 2 modes of operation. Manual and automatic. Index testing

is conducted using Manual control, but the machine normally runs under

Automatic control. It is important that the automatic mode gets thoroughly

checked out during its normal operation. After the optimization is complete and

the control system is back on automatic, double-check to make sure it’s doing

what it’s supposed to be doing. In this case it was not.

A

problem was found, right off the bat

There

was a bug in the vendor’s blade control software that caused inexplicable erratic

behavior on startup when the blades mounted the 3-D Cam. The machine had been

running for over a year with this problem and no one had noticed it - a good

argument for having an ITB around to allow viewing these things.

+

+

Figure 2 Cartesian coordinate animated display of ITB monitor

during Dorena Dam Kaplan startup

This

is the Cartesian coordinate display of Blade vs Gates the first time the ITB

got some StripChart data from Dorena. When the computer programmer who wrote

the 3-D Cam program saw what it was really doing, he recognized the problem and

immediately knew how to fix it. The program got fixed and a new was copy

installed the next day. This problem was never seen again. This demonstrates

the utility value of the Cartesian coordinate display format.

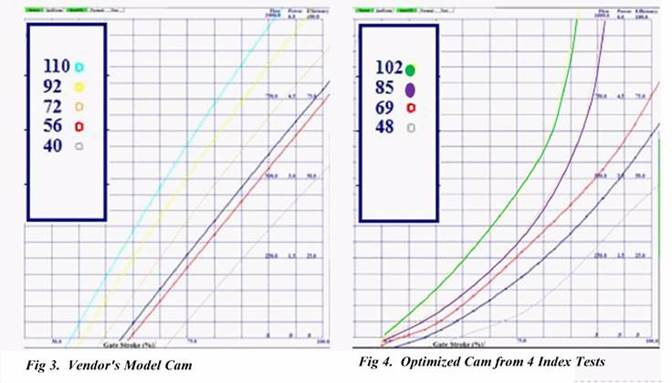

The

vendor’s cam surface (on the left, below) that came with the turbine from China

was only an approximation of the final optimized surface. Its only purpose was

to allow the new owner to startup and run the machine. After the unit is up and

running it should be optimized. Four separate index-tests, each optimizing the

gate to blade relationship at a single head were run at 69, 48, 85 and 102 ft

head. These 4 gate-to-blade curves were assembled into a 3-D surface to map-out

the entire operating envelope for the turbine (Fig. 4).

The

Dorena Dam Kaplan optimization project consisted of 4 separate index tests at 4

different heads to characterize the Optimum Cam curves across the full

head-range of the machine.

Data

Chain of Custody for ITB Hybrid Index Test Method data

This

boon came along quite by accident. Ordinarily acquiring an independent

commercial index test of this sort to validate the ITB would be an expensive

proposition ($50k and upwards), but this time we got lucky. ATECo was hired by

the seller to tune-up the 3-D Cam surface in the governor before closing the

deal. On behalf of the buyers, Hatch Inc ran the Load Reject and a separate

independent Index Test using the traditional methods. Unbeknown to Hatch Inc.

engineers, while they ran their Load Reject and index tests for the buyer the

powerplant datalogger was still streaming 2 Hz scans to memory. (If they’d have

known they’d probably have shut it off.) The recorder was always left on and

recording by the powerplant operators to capture anything interesting that may

happen to the unit… The owners and Northbrook Energy wanted to see the second

index test results so they shared the stripchart data. When asked, Hatch shared

a copy of their test report and the test data spreadsheet they used for this

commercial index test.

The

operators wanted the datalogger always recording scans at 2Hz so it captured

the Hatch’s Load Reject and index tests. A few weeks later this data was

uploaded to ATECo for analysis, and then the results were compared with Hatch’s

index test results. Because the input data was exactly the same for both tests,

the results from the two tests were also exactly the same after the

hair-splitting was sorted out. (except for a 0.4% peak efficiency

difference described below)

2017-05-16 Index Test at 102 ft gross head.wmv

Hatch

Kaplan Index Test

Report.pdf

This

comparison was discussed in detail with Peter Rodrigue, a senior engineer at

Hatch who signed off on the report.

Comparison of ITB and Hatch Dorena results with Peter Rodrigue.htm

My

answer and Hatch’s answer for the peak unit efficiency were different by 0.4%.

Contract guarantees ride on this percentage so it’s critical to get it right.

When Peter and I finished our fine-toothed comb treatment of the two sets of

calculations the conclusion was that the ITB was right and Hatch’s number was

0.4% too high. It was dismissed as a typo because the point was moot - there

was no Contract Guarantee in force so no harm, no foul.

The

question remains: After the head and blade to gate Kaplan turbine 3-D Cams are

tuned up and their efficiency profiles are delineated, what next?

Constant

Efficiency Monitor

The

example data for this next part of the presentation is a small 2-unit Francis

plant that had undergone runner refurbishment and was being restored to

service. A series of index tests were run to get data to justify going after

the Energy Tax Credit, but learned a bit more than they bargained for. This

example shows how index testing for diagnostics is a valuable protection from

loss and that a continuous efficiency monitor would have paid for itself many

times over. This video explains further: Francis

Continuous Monitor Pitch.wmv

The

ITB has a Condition Monitor mode that inputs from discreet sensors and/or a

SCADA system to compute real-time operating efficiency and then plots it on top

of the previously determined benchmark efficiency profile for the

existing head. The Condition Monitor will set off alarms if efficiency gets

outside of operator-preset limits above and below the benchmark. These animated

images show the screens on the Condition Monitor with various displays in

action.

Fig 5. Condition Monitor Display for 2 40 MW Francis turbines

The

Condition Monitor display above shows 4 stripcharts and 4 Cartesian coordinate

X-Y Displays of efficiency (kW/cfs) vs. flow (cfs). There are 2 units in this

powerplant so the X-Y graph displays were setup 2 per turbine to show both

full-range and zoom-in displays. The heavy center-line is the benchmark

efficiency profile extracted from the unit’s prior running data. The two

lighter lines above and below are computed operator-set limits boundaries. If

the computed efficiency gets outside of these limits, the dot changes color

from Green to Red and operator alarms are raised.

Fig 6. Condition Monitor Display for 1 40 MW Francis turbine

Here

is a closeup of the PI Recorder Data for one unit from this powerplant with 2

ea. 40 MW Francis units. The data scans are at 1-minute intervals 24/7.

This condition monitor shows at a glance the anticipated efficiency based on

prior running and the immediate real-time efficiency computed from current data

in real time.

Origin

and Test History of ITB

The

ITB was created as a new product at Woodward Governor Company in 1984 and has

been under continuous development ever since. Thus far on 5 separate occasions

the ITB has run side-by-side tests connected in parallel with traditional index

tests conducted and/or evaluated by government hydropower engineers. In every

case the ITB and traditional test results are in complete agreement.

The

ITB was 1st validated by field testing when its test results

agreed closely with a USACE Kaplan turbine acceptance test that had been run 2

weeks earlier at Clarence Cannon Dam.

1986-03-26 ITB Detailed Field Test (Albright)

1985-09-18 Clarence Cannon Test Report (Sachs)

A

2nd validation occurred 2-years hence when Lee Sheldon (while working

as a Hydropower Specialist at BPA) bought the first ITB from Woodward as a

commercial product to test at a dam near Portland Oregon. That demonstration

test went very well as reported by Portland General Electric (PGE) Sr. Staff

Engineer Gary Hackett who was a “Disinterested 3rd Party” who

participated in the test at Bull Run Dam (PGE-PHP-2).

1987-09-01 PGE-PHP-2 Report (Gary Hackett).

1988-05-28 PHP2 Classic Test (Sheldon)

1987-12-01 PGE-PHP-2 Report (Terry Bauman)

And

then Woodward exercised their Patent to quash all activity and the ITB project

languished on the back-burner. When the Patent expired in 2004 the ITB project

was resurrected to become a front-burner product for Actuation Test Equipment

Company.

The

3rd validation was by an index test on Unit 9 at USACE’s McNary Dam

in December 2015 that was compared to prior index testing conducted by

2005-12-12 McNary Field Test (Wittinger)

2006-01-16 McNary Field Test (Albright)

The

4th validation was by concurrent index testing at Ice Harbor Dam by

USACE HDC engineers. The government setup and ran an index test normally with

the ITB connected in parallel to record streamed data to memory, functioning as

a simple datalogger. The ITB was mis-programmed so that it recorded a test

point every few seconds instead of deriving a single steady-state data point

for 5 minutes of running time. When the data was received here the ITB was

reprogrammed to read this recorded data as if it were live field-measurements.

This method worked much better than expected and has evolved into the Hybrid

Index Testing (HIT) method.

http://www.actuationtestequipment.com/USACE_Docs/2006-03-28_ATECo_Ice_Harbor_Analysis.pdf

2006-03-28 ATECo Ice Harbor Analysis

2006-02-01 Ice Harbor data (Ramirez)

The

2 demonstrations for the government at McNary and Ice Harbor were deemed a

success but they chose not to buy it from ATECo.

2006-03-03 HOT Meeting PowerPoint (HDC).htm

The

5th validation was during the recent 4-head index test at Dorena Dam

when a traditional index was conducted by test by Hatch Inc. with the

powerplant datalogger recording 2 Hz scans. The ITB analyzed the datalogger

files used the HIT method and Hatch’s index test used the traditional methods.

The data for the exact same time intervals that Hatch took their measurements

was analyzed with the ITB. With the exact same source data

the computation routines in both methods gave the exact same answer.

2017-05-16 Index Test at 102 ft gross head.wmv

Hatch

Kaplan Index Test

Report.pdf

This

comparison was discussed in detail with Peter Rodrigue, a senior engineer at

Hatch who signed off on Hatch’s test report.

Comparison of ITB and Hatch Dorena results with Peter Rodrigue.htm

The

Next Step

Regarding

the maintenance program for 6 small hydro plants:

Here’s

a suggestion of how this could work:

Your

personnel will:

1.

setup your existing instrumentation

for an index test, adding new sensors as necessary to get the required signal

set.

2.

Reprogram your datalogger (or get

one if you don’t have one) to record 2-Hz Scans.

3.

Exercise the unit through the

requisite gate-blade pairs to execute an index test, dwelling for 3-minutes

settling time and another 5-minutes for data to record at each gate-blade pair.

4.

At any step in this process send a

sample of the datalogger recording to ATECo for spot-evaluation and critique.

(There is no charge for these.)

5.

Send the index test data to ATECo

for analysis and evaluation. (Up until this point no charge because the work as

all been done by your personnel).

6.

When a full set of turbine data is

reduced to a new cam-surface Best-Cam line for the tested head, the final

evaluation to get the 2-D Cam profile curve to put in the 3-D Cam costs $5k.

7.

This new cam curve will be merged into

the existing 3-D Cam, profile and returned. Send me as sample of your data

format and the new data will match it.

8.

As soon as you install the new cam

surface in the machine, rerun the index test procedure and upload the data to

ATECo.

9.

This new data will be analyzed and

computed with the before data for the unit to demonstrate how muck the index

test and optimization had helped.

10.

The deliverables ATECo will provide

will be:

·

A report of diagnostic observations

from the stripchart and X-Y Plotter

·

A data table of the SteadyState data

points gleaned from the continuous data recordings

·

A new on-cam curve to plug into the

3-D Cam for the tested head

·

If you provide your entire current

surface a new surface profile will be created by morphing the new data curve

for the tested head into it.

·

Before and after efficiency profiles

for the unit

·

Stripchart data.

How

to begin

The

first step is to inventory the turbine equipment.

1.

What kind of turbine is it?

2.

How many units are in the

powerplant?

3.

What kind of governors do they have?

4.

Is there a SCADA system?

5.

Is there a Data Logger?

And

then let’s talk about it and make a more specific plan.

Best

regards,

Douglas

Albright

Actuation

Test Equipment Company

(815)

335-1143