HYBRID INDEX TEST METHOD FOR

KAPLAN TURBINES

ACTUATION TEST EQUIPMENT COMPANY, INC

Winnebago, Illinois

August 27, 2017

Diagnostic Features

Kaplan gates and blades must be positioned accurately and robustly in order to maximize the turbine's generating efficiency and service life.

The first phase of any index test is a thorough checkout of the unit’s control system.

The Index Test Box (ITB) was developed at Woodward Governor Company in 1984 as a dual-purpose test instrument; the primary function is Kaplan turbine optimization to tune-up the 3-D cam surface profile. Secondary, but equal in import is the diagnostic analysis of the turbine control system behavior.

A third function for Condition Monitoring has recently been added to enhance the ITB’s utility value.

The ITB provided remote diagnositc analysis and index-testing capabilities using off-the-shelf IBM Pc type computers and data streamed from the existing powerplant SCADA system over normal office LAN or Ethernet communication.

This allows the engineers back in the office to

observe and diagnose turbine control systems behavior in the field, in real-time over

the Internet.

Setup and Instrumentation

Modern powerplant SCADA systems typically have the necessary instrumentation for an index test, except in some cases the Winter Kenney taps are non-existent or blocked with sediment. Every unit in every powerplant will be different.

To setup a unit for these tests the

governor is modified to provide signals to the SCADA system for gate setpoint,

blade setpoint, blade position and governor inputs are added for manual gate

and blade positioning. Many turbine governors don’t bring out these signals to

the SCADA system. In every case, the usual powerplant’s engineers and

technicians have been able to do this setup work. Next the SCADA system is

configured to bundle the required signals and route them to the existing powerplant

data logger.

1.

Forebay

2.

Tailwater

3.

Gate Setpoint

4.

Gate stroke

5.

Blade Setpoint

6.

Blade angle

7.

Flow (Winter Kennedy or

other flowmeter signal)

8.

Power (Watt transducer

output).

9.

Grid frequency

10.

Grid voltage

The powerplant data logger is reprogrammed to scan the above listed signal channels, add a scan-count and date/time stamp and record scans twice/second. Data is recorded continuously while the machine is operated normally.

Whenever an interesting event occurs, data files are sent by sneakernet to ATECo for analysis.

The first concern is to determine if the govenor is robust, accurate and precise enough for index-testing "on the governor."

The ITB software is not needed for most of these

checks - simply looking at the data in an Excel spreadsheet and knowing what to look for will show up many

of these problems.

Kaplan Off-Cam Index Testing Procedures

There are 3 ways to test a Kaplan turbine off-cam.

The most common is Fixed Blade, swept gates and power.

The second is Fixed Gate, swept blades and power.

The third is the Constant Power, moving gates and blades

The Fixed Blade method is the most commonly used because on most existing governor cabinets the gates are easier to control using the Gate Limit than the blades are to control by climbing up inside the governor cabinet to make adjustmenst to the thumbscrews on the blade hydraulic-amplifier's floating lever.

method is vastly superior for testing a single run of the river turbine with

small forebay and tailwater.

ITB Prototype Test Demonstration (1985-1986)

Woodward’s first ITB was

field tested in conjunction with the acceptance test of a 33MW vertical Kaplan at

USACE’s Clarence Cannon Dam. USACE test engineer Don Sachs was a proponent of

the Constant Power index testing

method that the ITB embodies, but HDC insisted that the classical Fixed-blade test method be used for his index test. This

author was recruited into his index-testing crew as the “governor man.” A12-man

USACE test crew performed the index test according to the procedures laid out in HDC’s

“Red-Book.”

Because Lee’s

tutorial on off-cam Kaplan index testing was the recipe used to design the

original ITB, both sets of test data were forwarded to Lee at BPA for

evaluation. Lee prepared a

comparative analysis report of these two data sets, prompting BPA to purchase

the first ITB from Woodward 6-months later.

Demonstration of Woodward’s ITB at Bull Run Dam (1987 to 1988)

When the original ITB was developed at Woodward Governor Company a U.S. Patent was acquired to protect the new instrument. The first test was at Portland General Electric’s (PGE) Bull Run Dam (PGE-PHP-2) located about 30-miles East of Portland, Oregon. The field-test at Bull Run went exactly to plan, according to field-test reports by Lee Sheldon, Gary Hackett (senior staff engineer from PGE) and Terry Bauman (The engineer that Woodward hired to take over the ITB project after I returned to Woodward’s aircraft development lab).

Because he didn't have a dog in the fight - Gary’s conclusion was the

most compelling of the three:

An

article in Hydro Review pitched

the new ITB from Woodward.

After this successful test BPA offered to procure

ITBs for all of USACE’s large Kaplan turbines in a project estimated to exceed

$30-million to acquire the new governors, 3-D Cams and ITBs, but instead of

accepting this FREE proven equipment that BPA would purchase from a world-class

supplier (Woodward) using DOE's funds, HDC engineers attempted to duplicate Woodward’s ITB with

their own design at DOE expense. A

BPA report on this project was acquired years later; despite the report’s encouraging

words the project had failed to achieve its objective and was quietly abandoned.

Woodward shelved and abandoned the ITB project after the government didn’t buy

them.

This

author quit Woodward in 1992 to startup the

Actuation Test Equipment Company (ATECo) to resurrect the ITB as a new

enterprise. When a prototype was ready Woodward was approached to add a

proven automatic

self-optimizing capability to their Kaplan governor. Threats

of lawsuits kept the ITB out of the market. Woodward didn't want

it, but they didn't want anyone else to benefit from it either.

This and other blunders by Woodward’s

hydro managers led the division to becoming so unprofitable that

corporate

managers sold the entire division to GE for $1 to sweeten the deal

when negotiations were underway to sell Woodward’s Engines and Turbines

division to GE. GE got the Patent with the hydro division, and

when they were approached with the ITB

a month later they were also not interested. So the ITB sat idle until

the patent expired 17 years later.

Experience with ITB at USACE HDC

(2003 to 2008)

In

2003 Lee was working at HDC as a rehired annuitant tasked with index

testing

all 113 of USACE’s large Kaplan turbines on the Columbia River under

the asupices of the fish-mortality lawsuit in Federal court. The patent

had

expired 2-years early because GE neglected to pay the 3rd renewal

fee. Rod Wittinger said he had been watching the Patent and when he saw it had expired,

directed Lee to contact this author to acquire the detritus of Woodward’s ITB

project as the start of a government project to resurrect the ITB - but ATECo

had already beaten them to it. HDC purchased a 2nd generation ITB

from ATECo on a government

contract after 2 sole-sourced solicitations (#1 #2).

A U.S.

Copyright was acquired to protect the software source code intellectual property. This version of

the ITB consisted of an IBM PC with a National Instruments I/O board and

Software Toolbox TopServer OPC communication program. The ITB was connected

directly to the GDACS SCADA system via a Cat-5 LAN cable and TopServer OPC program.

Figure 1 ATECo Pressure Transducer Cart with Electric

Flushing and Integral Air Compressor

A

pressure transducer cart was constructed by ATECo to facilitate moving the

ITB from machine-to-machine in a powerhouse. The ITB was deployed to McNary and

Ice Harbor Dams. At McNary, 2 ATECo personnel attended the test conducted by

government personnel. At Ice Harbor, government personnel ran the ITB without

anyone from ATECo present. The desired configuration had the ITB residing in

the control room and the transducer cart moved from machine to machine.

ITB Test at McNary Dam (December

2005)

Rod

Wittinger’s report on the test at McNary explains how the turbine was

manually exercised to the required gate and blade positions while the ITB

monitored the SCADA system’s data, and when Steady-state operation was detected

at each test point, the ITB automatically started recording data scans. Many

steady-state scans are collected at each test point and evaluated later by a

PostProcessor step to pick out the best test points. The ATECo

test report explains further.

Figure 2 ITB Test Data from McNary Dam

ITB Test at Ice Harbor Dam

(February 2006)

For

this test the ITB was only used to monitor and record data in parallel with a

classical Fixed Blade manual index

test conducted by HDC’s test engineers using their customary methods and tools.

When the test was completed, the “canned” data from the ITB was emailed to

ATECo for analysis. When the reduced result was returned, HDC’s engineer

charted the comparison of both results in an Excel® spreadsheet.

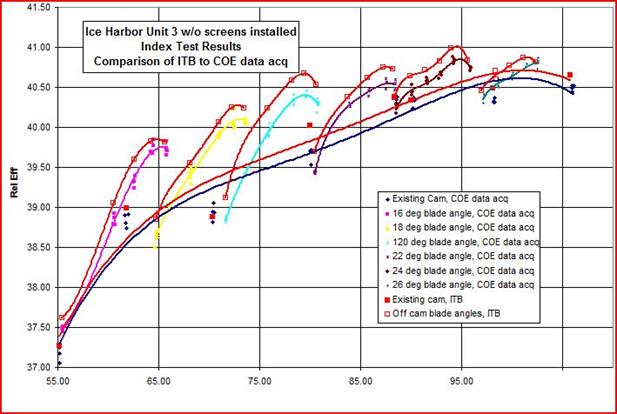

Figure 3 Index Test Results for COE and ATECo

Instrumentation

His

internal HDC memo reported on the test. The graph above has a slight offset

in the Winter Kennedy calibrations to show the similarity of the results. If

the calibrations had been equivalent, the efficiency curves would have laid right

on top of each other. In the subsequent test report to Bonneville Power

Administration (BPA) Hydro Optimization Team (HOT) USACE personnel said that

the ITB results were “Virtually

identical to those obtained using COE data acq system,” and that the ITB

was “Ready

for unattended automated data collection.”

Lee Sheldon* commented that the ITB data had less scatter than the

conventional data, falling closer if not right on top of the efficiency curves

for individual fixed-blade sweeps. After this successful test, instead of

buying the proven ITB from ATECo, government engineers initiated a project to

reverse-engineer the ITB in an internal government project. This all happened 10

years ago and by every indication (Periodic FOIA requests are keeping tabs on

them), they’ve been un successful just like when they attempted to duplicate Woodward’s

original ITB in 1990 with their “automatic

index testing device,” submitted to BPA as a potential surrogate to

Woodward’s ITB.

(*Please feel free to call Lee to

verify any of this, we’re currently working together on the project to index

test the 5MW turbine discussed herein: 503-356-8302)

Experience at Clergue Powerplant in

Sault Ste Marie (2009 to 2013)

The

best use of the ITB is when it can be connected to the SCADA system so that

sample rates of a KHz (more or less, depending on the computer and I/O board

selected) allow higher sample rates. A cavitation monitor and alarm in the ITB

would be a valuable feature, but due to powerplant politics and policies a

direct connection is forbidden. Most powerplants prohibit connecting strange, new

equipment (like the ITB) from unknown suppliers (such as ATECo) to their SCADA

system without first vetting the supplier and scanning for viruses and malware

- and in many cases there’s no money in the budget for it. This was the case at

Clergue in 2009. The ITB was demonstrated to work with North American Hydro’s

(NAH’s) new governors planned for the 3 turbines there. Dave Kornegay, NAH’s

project engineer had worked alongside me in 1984 when I developed the first ITB

at Woodward. Dave knew that the ITB would work for his governor designs at NAH

and wanted to add a “self-optimizing” feature to his Kaplan governor.

Unfortunately, Brookfield Renewable Power (BRP) had a policy of not allowing any

computing equipment or internet connections to their SCADA system and the money

for the new ITB hardware had not been approved. Dave really wanted this feature

on his governors, so along with Andrew Punkari (Andy) BRP’s project engineer,

Dave setup the governor software and prepared specifications for the governor,

powerplant instrumentation and SCADA system software changes; Andy programmed

the powerplant data logger to capture scans at a 2-Hz sample rate. All of this

was accomplished by the powerplant personnel using the pre-existing powerplant

equipment and sensors; most of the necessary signals were already in the SCADA

system so setting up the recorder was simple and straightforward. Data was

collected for several months and sent to ATECo periodically.

Another prohibition at

Clergue was because their contract with the power marketing agency stated that

if the machine was run in a test-mode (i.e. off-cam) the price paid for the

power was halved. BRP managers balked at the reduction in their revenue stream

so off-cam testing was disallowed. To get around this prohibition, a

blade-offset was added to the governor and HMI so that slightly off-cam data

could be acquired. Blade offsets were changed every few days, keeping within a

range of +3.0%. When the ITB test results were compared to the Hatch

Acres 2006 index test results good correlation was found. Unfortunately we were

unable to finish the testing because Andy was dispatched to

make repairs at another powerplant 200 miles distant and was gone for over a

year, so the ITB testing waited. Before he returned, Alstom bought NAH and Dave

jumped-ship to move to Innovative

Automation - who did not have a spot for the ITB in their product line.

Necessity is the Mother of Invention

By modifying the

existing governors, instrumentation, SCADA system and data logger to collect

the required data, and having the operators position the gates and blades

manually while the powerplant data logger stored 2 scan per second, the data

for a Kaplan off-cam index test can be collected in 4-hours. Low cost CDs,

thumb-drives and high-speed broadband Internet transfer of data files provide good

alternatives to a direct connection to the SCADA system. The most beneficial

result of this is the logistics of sending expert test personnel to the dam are

no longer necessary.

This

short video was prepared to publicize our method:

Figure 4 ITB SteadyState Analysis Display and Link to

Clergue Video

Click here:

Http://www.youtube.com/watch?v=C62uu2Cntx0

Current Field Test (December 2015

to present)

Lee

Sheldon got the job to index test a 5MW vertical Kaplan turbine and engaged

with ATECo to utilize the ITB’s Hybrid Index Testing capability for the job.

The facility is a flood control dam that was electrified after 63 years. An

index test was sought for the new 5MW vertical Kaplan to develop an optimized 3-D

Cam surface for this machine. An off-cam index test was needed to correct the

myriad issues that affect the optimum shape of a Kaplan turbine’s 3-D Cam head

and gate to blade surface.

Pre-Index Test Control System

Checkout

A

proper index test includes a dewatered inspection of the unit so that the

surface condition of water passageways and turbine working surfaces can be checked

and the full range of gate and blade motion can be verified from squeeze to

full open while the normal powerplant instrumentation and index testing

equipment are adjusted and calibrated. In lieu of such a comprehensive

inspection, with the above described modifications to the system software a

modest review of the data characteristics and time-response behavior can

determine if gate and blade movements conform to ASME and IEEE performance

standards. Below are a few examples of how this remote data observation

capability discovered problems with the Kaplan control system.

This

first check found a problem with the synchronizer. Getting a unit in sync with

the grid before closing the breakers on startup is a tedious and precise

requirement of the turbine control system. Most governor systems use an

external accessory such as Basler Electric’s

BE1-25A Automatic Synchronizer for this. This data from the 5MW Vertical Kaplan shows that

rotor bounces against the rotating magnetic field when the breaker is closed on

startup, which indicates the synchronization may not be adequate. This was seen

in typical operation data recorded during a normal startup.

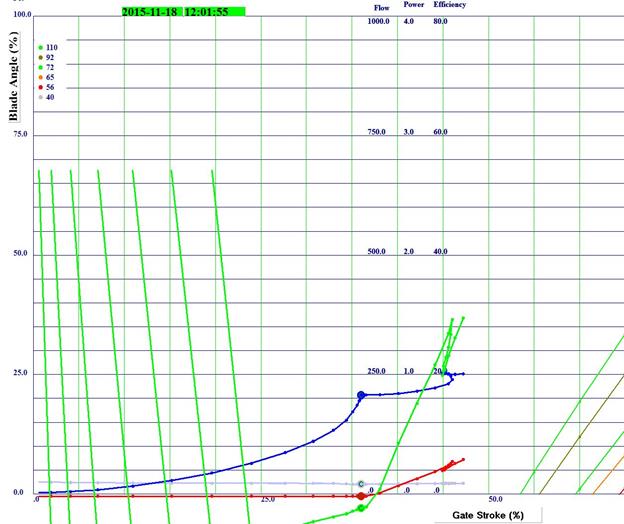

Figure 5 ITB Cartesian coordinate display during normal

startup

The

green lines on the left side are efficiency spikes that indicate the rotor was

not spinning at the same exact speed as the stator’s magnetic field when the

main breaker was closed. The unit should be at “speed-no-load” with flow but no

power generation i.e. a slightly negative efficiency value. What is happening

here is when the breakers close the rotor bounces against the rotating magnetic

field until it is pulled into synchronization. This may or may not damage the unit,

depending on how far out of sync the unit is when the breaker closes. In any

event, the control system should synchronize the unit to the grid better than

this for reliable long-term operation.

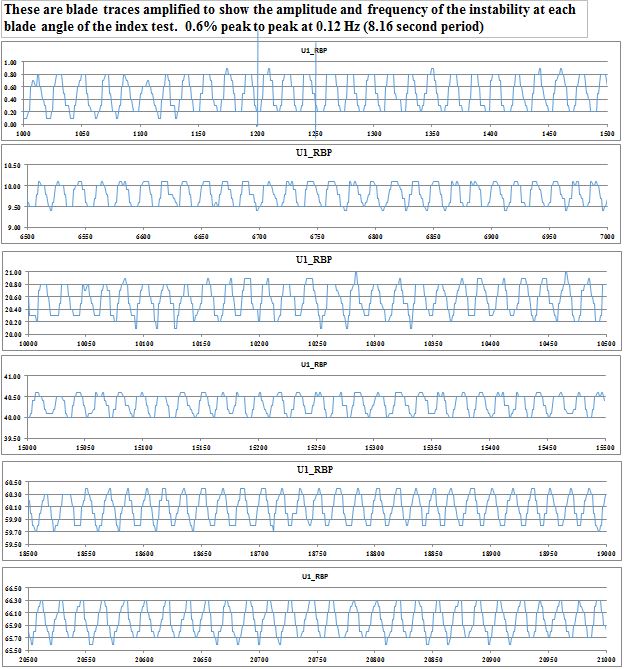

Another

problem was found in the stripchart traces from viewing the datalogger files

using Microsoft Excel®.

Figure 6 Excel® Stripchart Display Showing Blade Instability

At first glance the bottom trace in the chart above was

noticeably thicker than the others, so it was magnified at each blade value used

for the index test to investigate further. The Y Axis on these trace are blade angle

in percent and the X Axis is number of scans where each scan is 0.51 seconds

Figure 7 Excel® Stripchart Display of a Magnified View of the Blade Instability

This

blade trace display is magnified to show the amplitude and frequency of the

instability. The blades are always moving about 0.6% to 2.0% p-p with about an

8-second period. This is most likely caused by a positive lapped pilot valve on

the blade servo.

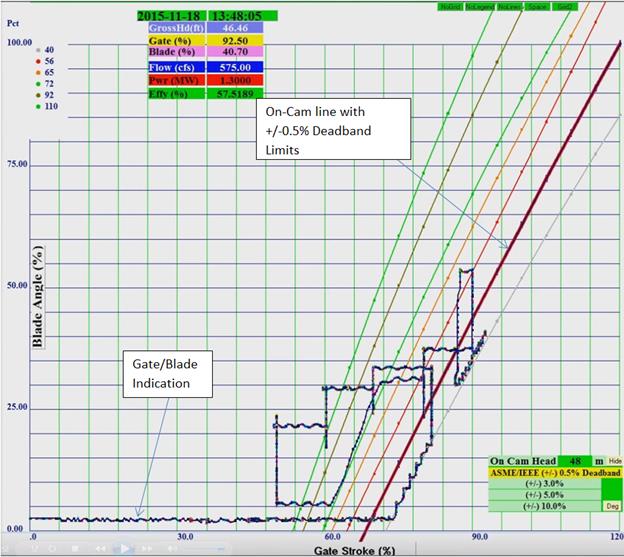

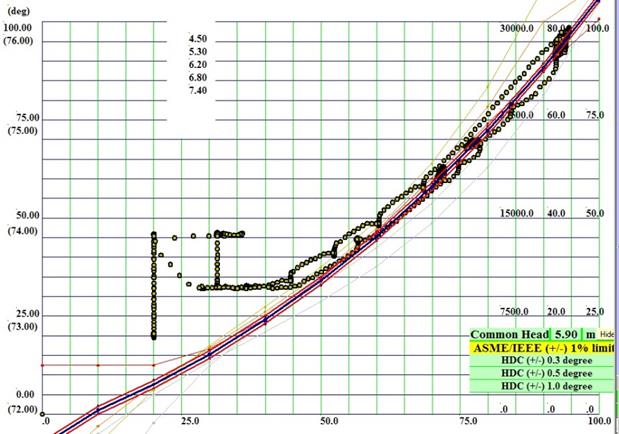

Another problem found

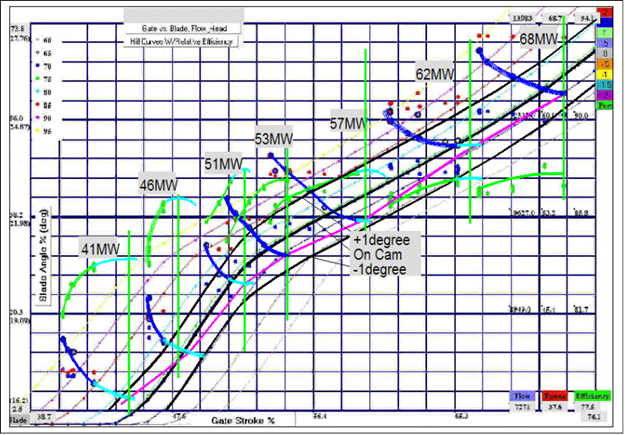

with the PLC-based Kaplan governor with a 3-D Cam and blade controller and an external

AGC in the SCADA system. This next graph shows the normal startup of this machine.

When generation is ramped up, the gate/blade indicator moved from left to right.

When it got to the 40-ft head line, the blades tracked up the 41ft blade cam

line instead of 46 ft, then the gates stop moving at 85% and the blades

continue going straight up, causing further increases of flow and power after

the gates stopped. At this point the AGC sees that power is too high and the

gates are closed a bit, and then the blades come back down a short time later.

This chart shows how the gates and blades continue to chase each other before

finally settling at the 41 ft on-cam line at the far right.

Figure 8 ITB Cartesian Coordinate Display showing 3-D Cam

Output Problem

This

chart shows conflicts between the governor, sluggish blade to gate relationship

and Automatic Generation Control (AGC). The two red lines immediately above and

below the heavy blue "On-Cam" line are the ASME prescribed 1.0%

deadband for proper blade positioning.

A

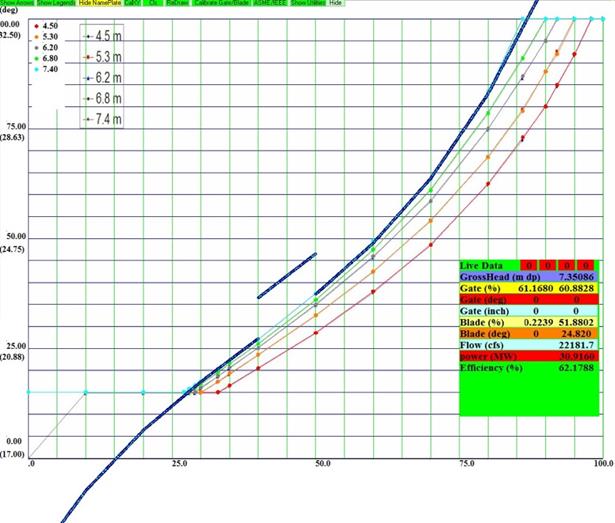

few more examples of problems detected at Clergue are included below:

Figure 9 ITB Display of Gate/Blade

motion of Kaplan Bulb Unit with NAH Governor

The chart above shows

the actual gate/blade relationship when the new governors were installed. The

blades and gates mostly track the on-cam line at the high end, but something

screwy is happening at the low end. Below 30% gate the blades change direction

and go up to about 45% blade angle instead of tracking down along the on-cam

line. When this was showed to the governor engineer he consulted with the

programmer and this got fixed.

Figure 10 ITB Display of Gate/Blade

motion of Kaplan Bulb Unit with NAH Governor 3-D

Cam Data Table Bug

A second problem was

seen in the on-cam line when head was above 6.8m. The cause was an error in the

lookup table at the highest head. Again, as soon as the problem was seen, the

programmer slapped his forehead and fixed it in a jiffy. Without this Cartesian

coordinate display he wouldn’t have caught this problem until it was in the

field, and then he’d be fixing this under the customer’s nose.

Conclusion

These

real-world problems are not presented herein to be critical of anyone’s workmanship;

instead they are here just to show the utility value of observing the gate/blade

behavior of a Kaplan unit with an X-Y Cartesian coordinate display in the

field. If the problems can be observed and repaired during installation and

setup of the governor, everything will go smoother. In many cases, the decision

makers are business types or civil engineers; unfamiliar with governors and

their dynamic requirements.

Sincerely

yours,

Douglas

Albright

Actuation

Test Equipment Company

(815)

335-1143